We have over 45 years experience in paint spraying and pumping, with Graco being our primary supplier.

Why Spray?

Speed: Spraying is faster meaning more work can be completed in less time using less labour. It can be up to 5 times faster than brushing or rolling.

Quality: Spraying produces an even coat of paint leaving a high quality finish. Can be sprayed on to all types of surfaces.

Versatility: Spraying can be used for a wide range of coating materials which includes protective coatings to high quality cosmetic finishes.

Plural Component Mixing

This is a method which automatically proportions two or more component paint materials for spraying.

Benefits:

Improved durability: Plural component mixing will withstand abusive conditions better than other paints.

Better Chemical Resistance: Plural component mixing will withstand chemical exposure better than other paints.

Increased flexibility: Plural component mixing is less likely to crack on plastic substrates when impacted (polyurethanes)

Lower energy cure: Ovens can be run at lower temperatures when using plural component spraying.

Faster cure times: Plural component mixing allows for the paint to cure faster

Reduces VOC’s: Plural component mixing has a lower Volatile Organic Compounds (VOCs)

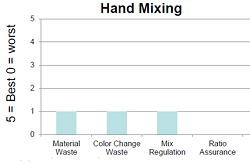

Hand Mixing

Wasted Material: Whatever is not sprayed after material becomes too thick

Ratio Accuracy: Limited to operator’s ability when hand mixing

Ratio Assurance: Hand mixing has no ratio assurance and you can find bad parts when they don’t cure

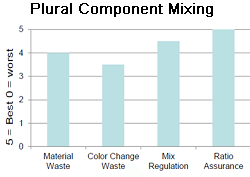

Plural Component Mixing

Wasted Material: Flush material inline with solvent also reduces colour change time and waste.

Ratio Accuracy: Excellent, within 1%, user settable tolerance.

Ratio Assurance: Excellent, shuts down when not meeting ratio tolerance.

We have a wide range of paint spraying equipment on offer and have experienced personnel who specialise in Graco machinery. For more information on the paint spraying equipment we stock please visit our Spray and Pump section.